info@nunesinstruments.com - GST NO. : 33AAIPN8819N1Z3

- Send Email

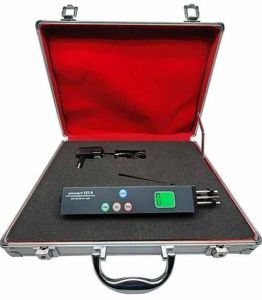

| Business Type | Exporter, Supplier, Trader |

| Type | Digital Gas Pressure Gauge |

| Use | Gas |

| Display Type | Digital |

| Click to view more | |

Product Details

A digital pressure gauge is a precision instrument used to measure the pressure of gases or liquids within a system and display the measurement digitally. Unlike traditional analog pressure gauges, which use mechanical components (such as springs and dials), digital pressure gauges use electronic sensors and microprocessors to generate and process pressure readings.

Key Features and Components:

Pressure Sensor (Transducer): The heart of a digital pressure gauge is a pressure sensor, which detects changes in pressure. This sensor could be a strain gauge, capacitive, piezoelectric, or a resonant sensor, depending on the design and application. The sensor converts the mechanical pressure into an electrical signal.

Microprocessor/Display: The electrical signal from the pressure sensor is processed by a microprocessor. The microprocessor then converts this signal into a numerical value, which is displayed on a digital screen, usually an LCD or LED display.

Power Supply: Digital pressure gauges are powered by batteries, rechargeable batteries, or a direct connection to a power source, depending on the model. Some advanced models can also be powered via external sources like 4-20 mA or RS485 signals.

Units and Calibration: Digital pressure gauges can be calibrated for different pressure units, such as psi (pounds per square inch), bar, pascal (Pa), or kilopascal (kPa), allowing for flexibility in various applications. The calibration process ensures accurate readings based on the intended measurement range.

Additional Features:

Data Logging: Some digital pressure gauges are equipped with data logging capabilities, allowing them to store pressure readings over time for later analysis.

Looking for "Digital Gas Pressure Gauge" ?

Explore More Products